Handbook Of Cleaning In Semiconductor Manufacturing: Comprehensive Guide (EPUB, PDF, MOBI)

Are you searching for the ultimate resource on cleaning processes in semiconductor manufacturing? Look no further. The Handbook of Cleaning in Semiconductor Manufacturing is a must-have guide for engineers, researchers, and professionals in the semiconductor industry. This comprehensive resource dives deep into the critical role of cleaning in ensuring the quality and reliability of semiconductor devices. In this article, we will explore the importance of this handbook, its key features, and how you can access it in various formats like EPUB, PDF, and MOBI. Whether you're a beginner or an expert, this guide will provide valuable insights into the intricate world of semiconductor cleaning.

Cleaning is a fundamental step in semiconductor manufacturing, as even the tiniest particle or contaminant can compromise the performance of a device. The Handbook of Cleaning in Semiconductor Manufacturing addresses this critical aspect by offering detailed methodologies, cutting-edge technologies, and best practices for achieving pristine surfaces. This handbook is not just a theoretical guide; it also includes practical applications, case studies, and industry standards to help professionals optimize their processes.

With the increasing complexity of semiconductor devices, the need for advanced cleaning techniques has never been greater. This handbook serves as a bridge between theory and practice, making it an indispensable tool for anyone involved in the semiconductor industry. Whether you're looking to improve your current cleaning processes or stay updated with the latest advancements, this article will provide you with all the information you need.

Read also:The Evolution Of Floyd Mayweather From Amateur To Boxing Legend

Table of Contents

- Introduction to the Handbook

- Importance of Cleaning in Semiconductor Manufacturing

- Key Features of the Handbook

- Cleaning Techniques Explored

- Industry Standards and Best Practices

- Case Studies and Practical Applications

- How to Access the Handbook (EPUB, PDF, MOBI)

- Benefits of Different Formats

- References and Further Reading

- Conclusion and Call to Action

Introduction to the Handbook

The Handbook of Cleaning in Semiconductor Manufacturing is a comprehensive resource designed to address the challenges and complexities of cleaning processes in the semiconductor industry. Written by experts with decades of experience, this handbook provides a detailed overview of the principles, techniques, and technologies involved in semiconductor cleaning. It is structured to cater to a wide range of readers, from beginners to seasoned professionals, making it an invaluable tool for anyone looking to enhance their knowledge in this field.

Who Should Read This Handbook?

This handbook is ideal for:

- Engineers working in semiconductor fabrication facilities.

- Researchers studying advanced cleaning technologies.

- Professors and students in materials science and engineering programs.

- Industry professionals seeking to stay updated with the latest trends.

By covering both theoretical and practical aspects, the handbook ensures that readers gain a holistic understanding of semiconductor cleaning processes.

Importance of Cleaning in Semiconductor Manufacturing

Cleaning plays a pivotal role in semiconductor manufacturing, as even microscopic contaminants can lead to defects in the final product. The Handbook of Cleaning in Semiconductor Manufacturing emphasizes the significance of maintaining ultra-clean environments to ensure the reliability and performance of semiconductor devices.

Impact of Contaminants

Contaminants such as particles, organic residues, and metallic impurities can cause:

- Short circuits in integrated circuits.

- Reduced device yield and reliability.

- Increased manufacturing costs due to rework or scrap.

By implementing effective cleaning processes, manufacturers can minimize these risks and produce high-quality semiconductor devices.

Read also:Bo Basset Birthday Celebrating The Life Of A Rising Star

Industry Trends

With the rise of nanotechnology and advanced semiconductor nodes, the demand for precision cleaning has increased significantly. The handbook explores these trends and provides insights into how the industry is adapting to meet these challenges.

Key Features of the Handbook

The Handbook of Cleaning in Semiconductor Manufacturing stands out due to its comprehensive coverage and practical approach. Below are some of its key features:

Detailed Methodologies

The handbook provides step-by-step methodologies for various cleaning techniques, including:

- Wet chemical cleaning.

- Plasma cleaning.

- Ultrasonic cleaning.

Case Studies

Real-world case studies are included to demonstrate how these techniques are applied in industrial settings. These case studies offer valuable lessons and practical insights for readers.

Cleaning Techniques Explored

The handbook delves into a wide range of cleaning techniques used in semiconductor manufacturing. Each technique is explained in detail, with a focus on its advantages, limitations, and applications.

Wet Chemical Cleaning

Wet chemical cleaning is one of the most widely used methods in semiconductor manufacturing. It involves the use of chemicals to remove contaminants from surfaces. The handbook provides detailed protocols for preparing and applying these chemicals safely and effectively.

Plasma Cleaning

Plasma cleaning is a dry cleaning method that uses ionized gas to remove organic contaminants. This technique is particularly useful for delicate surfaces that cannot withstand wet processes.

Industry Standards and Best Practices

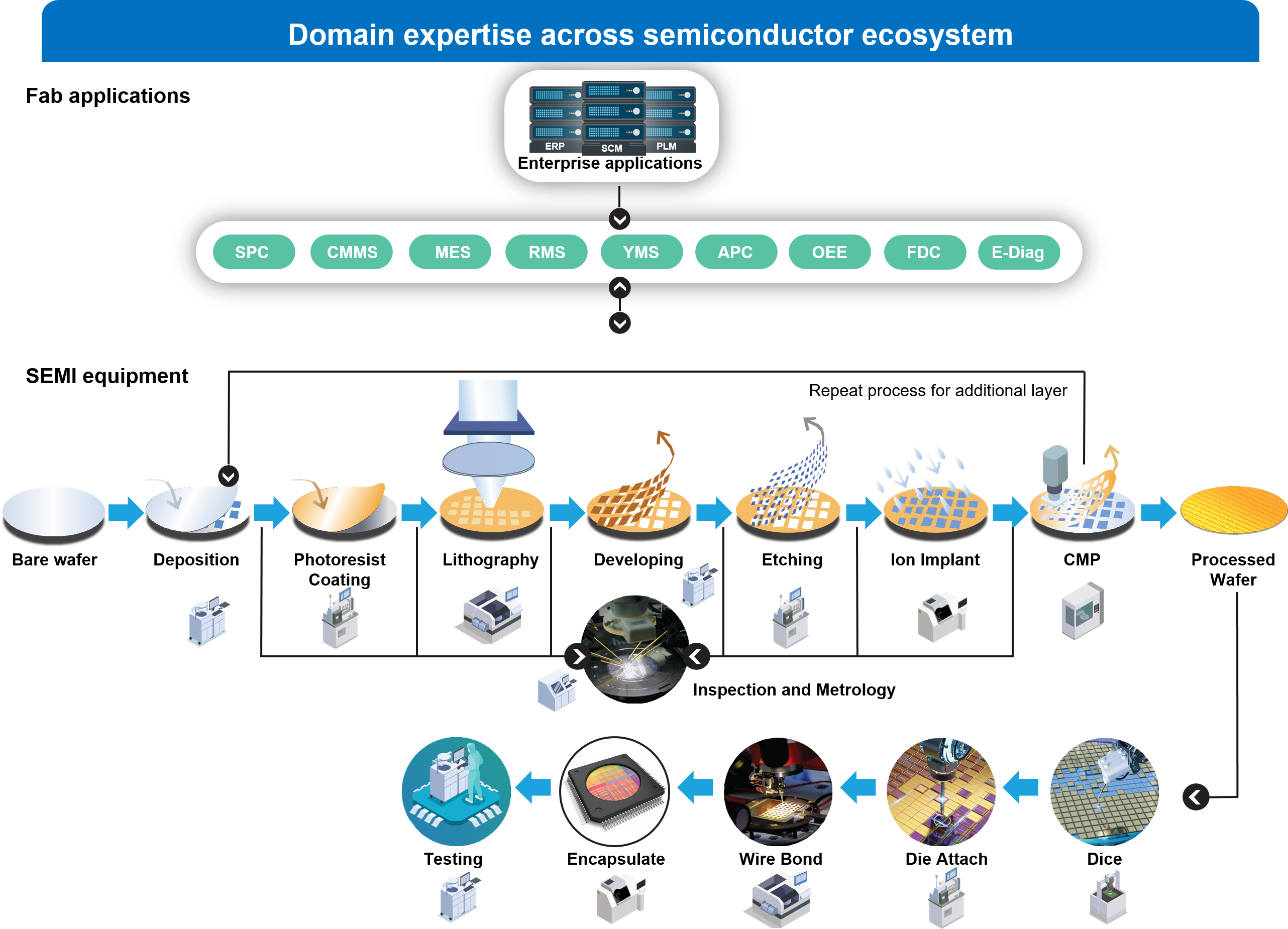

Adhering to industry standards is crucial for ensuring the effectiveness of cleaning processes. The handbook includes a comprehensive overview of relevant standards, such as those from SEMI (Semiconductor Equipment and Materials International).

Best Practices for Implementation

Some best practices highlighted in the handbook include:

- Regular monitoring of cleaning processes.

- Use of high-purity chemicals and materials.

- Training employees on safety protocols.

Case Studies and Practical Applications

The handbook features several case studies that illustrate the practical application of cleaning techniques in real-world scenarios. These case studies are drawn from leading semiconductor manufacturers and research institutions.

Case Study: Reducing Defects in Wafer Production

One case study focuses on how a major semiconductor company reduced defect rates by implementing advanced plasma cleaning techniques. The results demonstrate a significant improvement in yield and product quality.

How to Access the Handbook (EPUB, PDF, MOBI)

The Handbook of Cleaning in Semiconductor Manufacturing is available in multiple formats to suit different preferences. Whether you prefer reading on your e-reader, tablet, or computer, you can access the handbook in EPUB, PDF, or MOBI formats.

Where to Download

You can download the handbook from reputable platforms such as:

- Publisher's official website.

- Online libraries and academic databases.

- Authorized e-book retailers.

Benefits of Different Formats

Each format offers unique advantages:

- EPUB: Ideal for e-readers and mobile devices, offering a reflowable layout.

- PDF: Perfect for printing and offline reading, with a fixed layout.

- MOBI: Compatible with Kindle devices, providing a seamless reading experience.

References and Further Reading

To support the information provided in this article, we have referenced several authoritative sources, including:

- SEMI standards for semiconductor manufacturing.

- Research papers on advanced cleaning technologies.

- Industry reports on semiconductor trends.

Conclusion and Call to Action

The Handbook of Cleaning in Semiconductor Manufacturing is an essential resource for anyone involved in the semiconductor industry. It provides a comprehensive overview of cleaning techniques, industry standards, and practical applications, making it a valuable tool for improving manufacturing processes.

We encourage you to explore this handbook and share your thoughts in the comments section below. If you found this article helpful, please share it with your colleagues and peers. For more in-depth articles on semiconductor manufacturing, visit our website and stay updated with the latest industry trends.

Understanding ISO 15630-3: A Comprehensive Guide To Steel Testing Standards

Loose-Leaf Essentials Of Investments Answers: A Comprehensive Guide

The Pemeran In The Dark Knight Rises: Unveiling The Iconic Characters And Their Impact

Semiconductor Manufacturing Handbook, 2nd Edition, Hwaiyu Geng

Semiconductor Equipment Manufacturing Industry Services, 41 OFF